INSTALLATION OF A RECTANGULAR POLYPROPYLENE PLASTIC POOL

In any case, our plastic pools must be sunk underground so that they can protrude at least 30 cm from the ground, and the top of the pool must not be below the ground level.

The installation process consists of the following steps:

- Digging a working pit

The size of the working pit does not match the size of the selected pool! When digging, it must be taken into account that each side must be increased by at least 10 cm compared to the size of the pool body. The depth of the pit should be 22 cm greater than the original depth of the pool body.

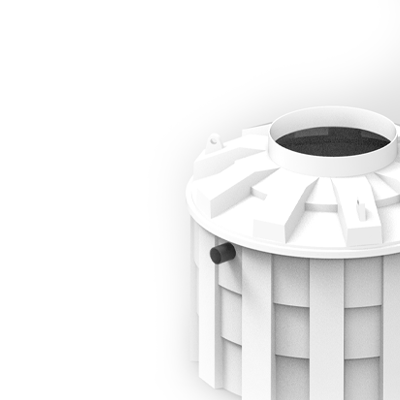

It is necessary to deepen a working pit on one side of the pool of the mechanical shaft. The mechanical shaft must be placed on a flat, solid base, and a working pit 15-15 cm larger on each side than its dimensions must be taken.- Socket design

The foundation is only possible on a solid ground surface. A 5 cm thick 0-8 mm gravel bed is required as the first layer, followed by a 15 cm thick layer of reinforced concrete. It is recommended to place a 10 mm 15 cm x 15 cm welded flat mesh in the concrete with an overlap.

It should be taken into account that the drying time of the concrete is 12-18 days, depending on the weather. Care and watering of the concrete is necessary during the drying time.

The top layer can only be placed after this, which is a 2 cm XPS insulating sheet - this must be placed over the entire area of the substrate.

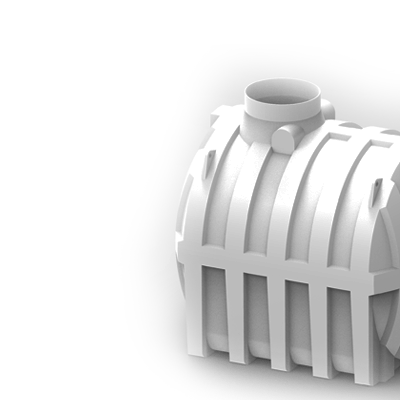

On the side of the pool, the ribs are designed in such a way that the ribs are placed 60 cm apart, so that the 4 cm XPS insulation boards can be easily placed inside.

- Placing a pool in the working pit

The pool body can be easily moved with the help of 6-8 people, lowering it into the pit is not a big task.

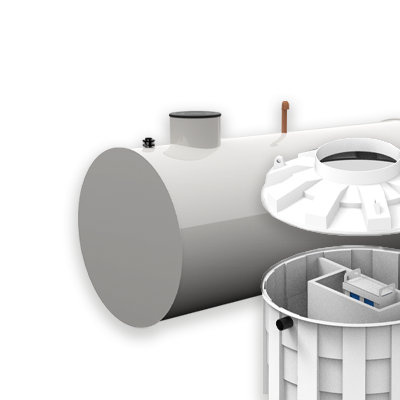

It is possible to lift the pool with a crane or a work machine. The holes placed on the stiffening ribs serve two purposes: one is for securing the binding during transport, and the other is when the pool body is lifted, these points can be used as lifting lugs.

3 + 1. Connecting mechanical elements to the network

If you have ordered some extra elements from us (LED lamp, heat pump, etc.), they must be connected to the network when the pool body is already in place, but the backfilling has not yet taken place.

- Backfilling the sides of the pool